Product Details

Solids Control Equipment

Solids control equipment plays a pivotal role in the oil and gas drilling industry. Its primary function is to remove solid particles from the drilling fluid, ensuring the fluid’s optimal performance and safeguarding the overall drilling operation.solids control equipment is an essential component of any drilling operation, contributing to both the economic and environmental sustainability of the oil and gas industry.

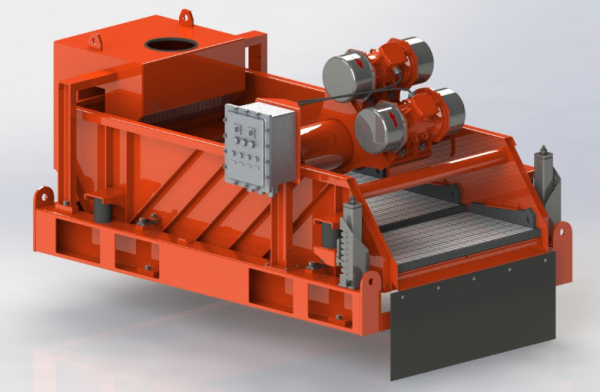

Shale Shakers

Shale shakers are the first line of solids control. They use vibrating screens to separate large solid particles from the drilling mud. Equipped with advanced screen tensioning systems, these shakers ensure consistent screening performance. The high- G force vibration efficiently conveys solids off the screens, while the adjustable stroke and frequency settings enable operators to adapt to different drilling conditions.

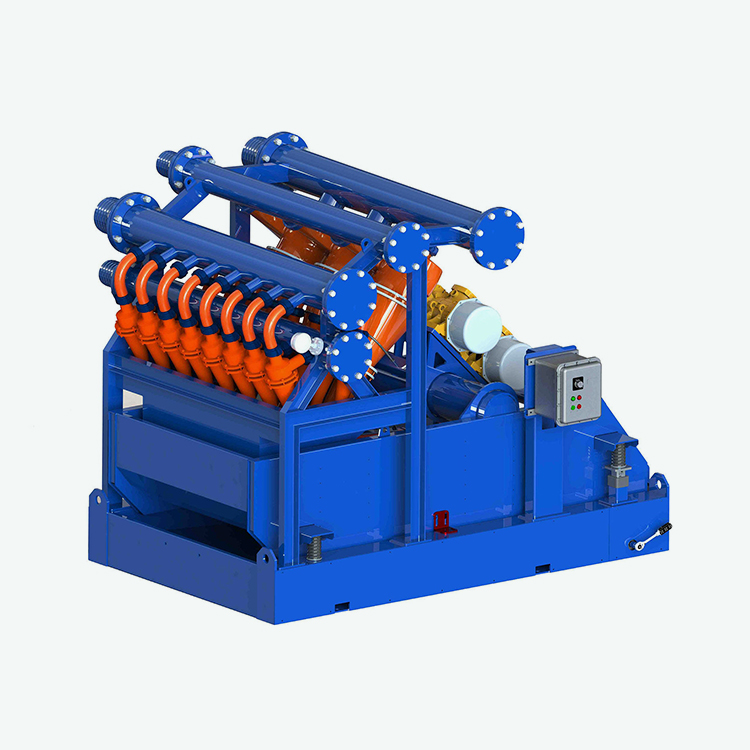

Hydrocyclones

Hydrocyclones, including desanders and desilters, operate on the principle of centrifugal force. In a hydrocyclone, the drilling fluid enters tangentially, creating a swirling motion. Heavier solid particles are forced to the outer wall and discharged through the underflow, while the cleaner fluid exits through the overflow. Desanders are designed to remove larger sand - sized particles (40 - 200 microns), and desilters target smaller particles (5 - 40 microns).

Centrifuges

Centrifuges are the final stage of solids control, used to separate fine - grained solids from the drilling fluid. They operate by spinning the fluid at high speeds, causing the denser solids to settle against the walls of the centrifuge bowl. The solids are then discharged through a conveyor system, while the clarified fluid is collected. High - speed centrifuges can achieve very fine separation, removing particles as small as 2 - 5 microns.

Mud Cleaners

Mud cleaners are a combination of shale shakers and hydrocyclones. The hydrocyclones pre - separate medium - sized particles from the drilling fluid, and the shale shaker further processes the underflow, effectively recovering valuable drilling mud and reducing waste.By removing solid contaminants, solids control equipment helps to:

- Enhance drilling efficiency: Clean drilling fluid flows more easily through the drill string, reducing friction and improving the rate of penetration.

- Protect drilling equipment: Solid particles can cause abrasive wear on pumps, drill bits, and other components. Removing these particles extends the lifespan of the equipment.

- Meet environmental regulations: Proper solids control minimizes the release of harmful drilling waste, ensuring compliance with environmental standards.