Product Details

Gate valves

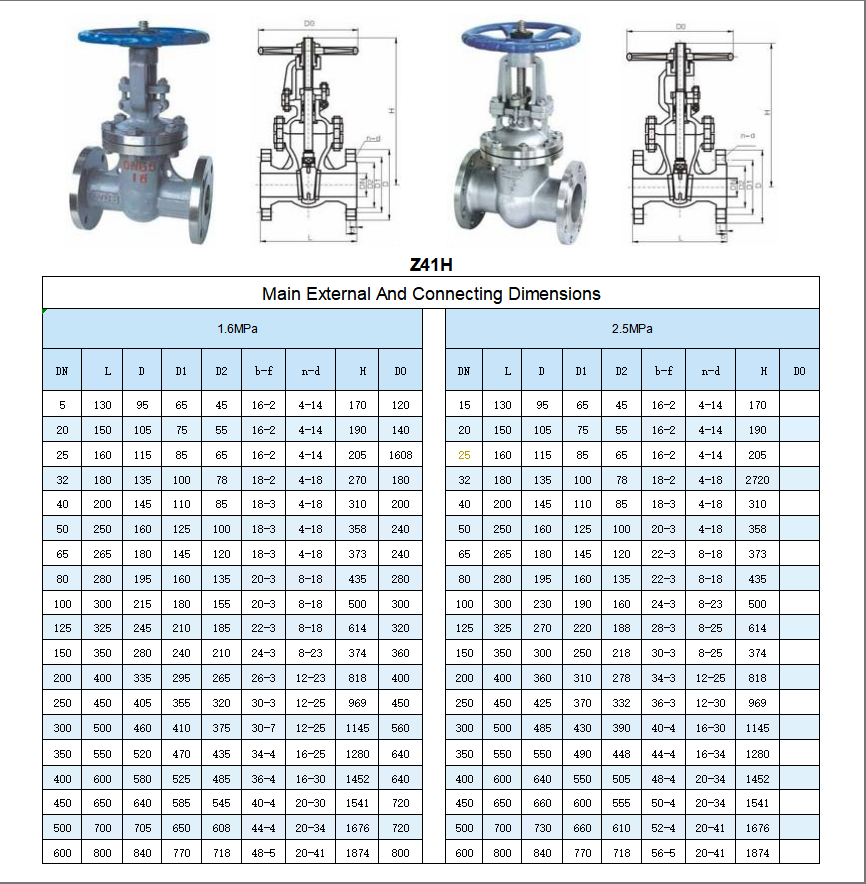

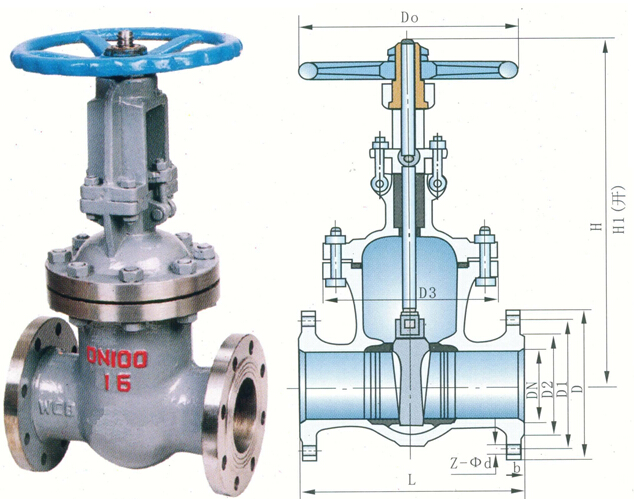

Gate valve is a type of valve used to control the flow of fluids in a pipeline. Gate valve mainly consists of a valve body, a gate, a stem, and a packing gland. The valve body provides the housing and connection points for the pipeline. The gate is the key component that controls the flow, and it is connected to the stem. The stem is used to raise and lower the gate. The packing gland is used to seal the stem to prevent fluid leakage.When the stem is rotated, it drives the gate to move up and down. When the gate is fully opened, the fluid can flow through the valve with minimal resistance. When the gate is completely closed, it blocks the flow of fluid, achieving the purpose of shutting off the pipeline.

Characteristics

Low Flow Resistance: When the gate valve is fully open, the fluid can flow through the valve in a straight line, with very low flow resistance, which is beneficial to the smooth flow of fluid in the pipeline and can reduce energy loss.

Good Sealing Performance: Gate valves usually have good sealing performance. The gate and the valve seat are in close contact to ensure that there is no leakage when the valve is closed, which is very important for the transportation of fluids that require high - tightness.

Wide Applicability: Gate valves can be used in a variety of fluid media, including water, steam, oil, and gas. They are suitable for different working pressures and temperatures, with a wide range of applications.

Applications

Gate valves are widely used in various industrial fields and urban pipeline systems. In the water supply and drainage system, they are used to control the flow of water in the pipeline. In the heating and steam system, they are used to adjust the flow of steam. In the oil and gas pipeline transportation, they are used to control the flow of oil and gas. In short, wherever the fluid needs to be cut off or the flow needs to be controlled, the gate valve is a commonly used valve.

Classification

Parallel - Slide Gate Valve: The gate moves in a parallel direction to the valve seat. It usually has two parallelgate plates, which are connected by a spring or other mechanism. This type of valve is suitable for applications where the medium has a certain viscosity or contains some impurities, as the parallelslide structure is less likely to be jammed. It is commonly used in oil and gas transportation pipelines.

Manual Gate Valve: It is operated by manual rotation of the handle or wheel. This type of valve is simple in structure and easy to operate, suitable for occasions where the operation frequency is not high and the pipeline pressure is relatively low, such as in some small - scale water - supply systems in residential areas.

Electric Gate Valve: Driven by an electric motor, it can achieve remote control and automatic operation. It is widely used in large - scale industrial production and urban - pipeline systems where centralized control and high - automation are required. For example, in a chemical - plant's pipeline system, electric gate valves can be controlled centrally through a programmable logic controller (PLC) to ensure the accurate control of fluid flow.

Pneumatic Gate Valve: Powered by compressed air, it has a fast response speed and can be used in environments where explosion - proof requirements are high. In some oil - and - gas - extraction fields, pneumatic gate valves are preferred because they can avoid the risk of explosion caused by electric sparks.

Hydraulic Gate Valve: Utilizes hydraulic pressure to drive the gate. It can provide large - driving force and is suitable for applications with high - pressure and large - diameter pipelines, such as in some water - conservancy - project - related pipeline systems.

Flanged Gate Valve: Connects to the pipeline through flanges. It has a large connection surface and can bear high pressure. It is widely used in various industrial pipelines and urban - water - supply - and - drainage pipelines. The flange connection is easy to install and maintain, and it can ensure the tightness of the pipeline connection.