Product Details

HDPE pipe

HDPE pipe, that is, high-density polyethylene pipe, is a kind of plastic pipe made of high-density polyethylene (HDPE), which has many characteristics and wide application fields.

HDPE is a non-polar thermoplastic resin with high crystallinity, good chemical resistance, wear resistance and impact resistance. Its molecular structure is compact, which makes it have high strength and rigidity. Usually, the extrusion molding process is adopted, and the pretreated HDPE particles are added into an extruder, melted by heating and pressing, and then extruded by a die to form pipes with different specifications and sizes. In the production process, some additives, such as anti-ultraviolet agent and antioxidant, can be added as needed to improve the performance of the pipe.

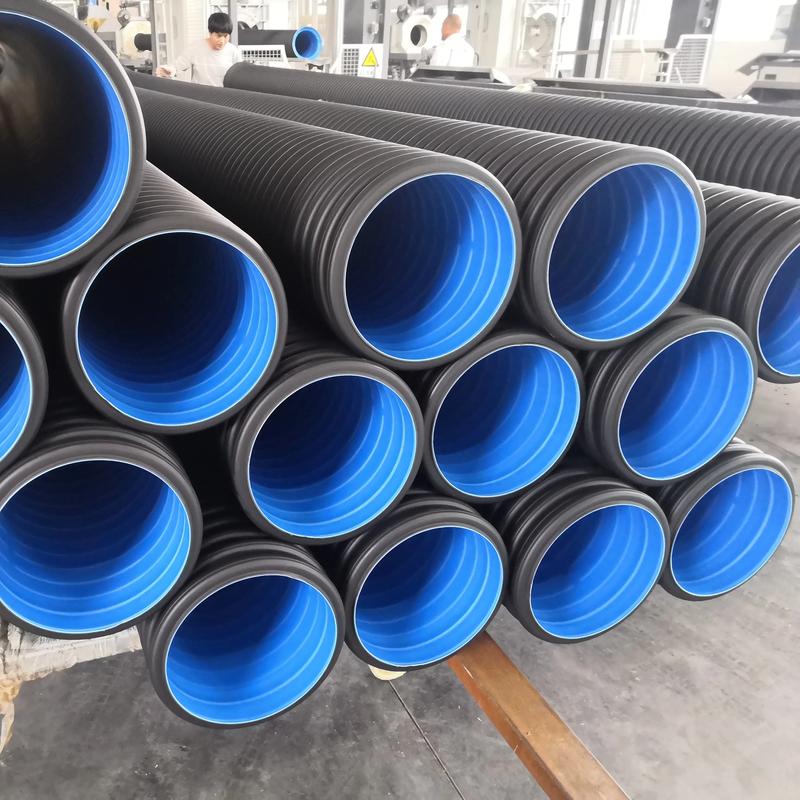

HDPE Bellows Pipe

Structure and Manufacturing: HDPE bellows pipe, also known as HDPE double - wall corrugated pipe, is made of high - density polyethylene through an extrusion molding process. Its inner wall is smooth and flat, while the outer wall is in the shape of trapezoidal or arc - shaped corrugated ribs, with a hollow structure between the inner and outer walls.

Product Characteristics:

- Unique structure and high strength: The annular corrugated structure on the outer wall greatly enhances the ring stiffness of the pipe, enabling it to better resist soil pressure.

- Smooth inner wall, low friction resistance, and large flow capacity: It can reduce the resistance during fluid transportation and improve the efficiency of fluid transmission.

- Convenient connection and good joint sealing: It is easy to install and has a reliable sealing effect, which can effectively prevent leakage.

- Light weight and fast construction: It is convenient to carry and install, which can shorten the construction period and reduce labor costs.

- Resistant to acid, alkali, and corrosion: It has excellent chemical stability and can be used in various harsh environments, with a buried service life of more than 50 years.

- Wide temperature range: It can work in the temperature range of - 10℃ to 45℃. It has good frost - resistance and cold - resistance performance.

HDPE Solid - Wall Pipe

Material and Manufacturing: HDPE solid - wall pipe is made of high - density polyethylene, which is a crystalline, non - polar thermoplastic resin. It is formed by hot extrusion through an advanced production process and technology.

Product Characteristics:

- Long service life: Under normal conditions, it can be safely used for at least 50 years.

- Good hygiene: It is non - toxic, does not contain heavy metal additives, does not scale, and does not breed bacteria, which well solves the problem of secondary pollution of drinking water.

- Resistant to various chemical media: It has excellent corrosion resistance and no electrochemical corrosion.

- Smooth inner wall: The friction coefficient is extremely low, which can improve the passing capacity of the medium and has excellent wear - resistance.

- Good flexibility and high impact strength: It has strong earthquake - resistance and torsion - resistance.

- Light weight: It is convenient for transportation and installation.

- Reliable connection: The unique electro - fusion connection, hot - melt butt joint, and hot - melt socket connection technologies make the joint strength higher than that of the pipe body, ensuring the safety and reliability of the joint.