Product Details

Mud Pump and Parts

F Serial Mud Pump

Design and Features

The combination lubricating method of forced lubrication and spray lubrication ensures more effective lubrication.

The durable and compact F series NMD pump with advanced structure improves the pump's stable operation. It can meet special demands of customers in middle & deep drilling works.

It's small and durable. The injection valve and bleed valve can change mutually, so can the three cylinders of each pump and main parts of fluid end.

The durable fluid end of F series mud pump improves the performance of triplex mud pump greatly. Besides, its independent design is convenient to be examined and maintained.

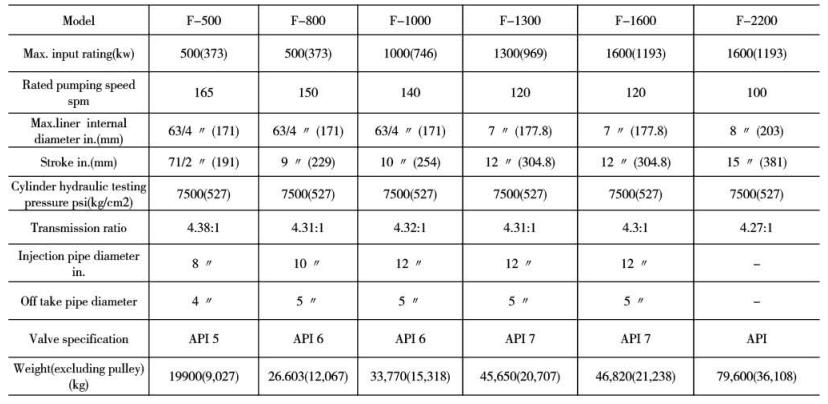

F Serial Mud Pump Parameter

3NB Mud Pump

Design and Features

The shell is of plate welding structure, which eliminates internal stress after welding. The power transmission gear is involute gear type, ensuring stable operation, high efficiency, and long service life. The crank is a hollow complete casting, and the method of lubrication is spray lubrication.

The bottom of the valve hole has steps to prevent the valve seat from falling. The piston and liner are cooled and lubricated by an independent spray pump system, which ensures a long service life.

The piston and crosshead pin beam are connected by a lathe dog, which allows rapid installation and removal.

Liquid end: The injection and outlet flange comply with API and ANSI regulations.

The vulnerable parts have strong interchangeability.

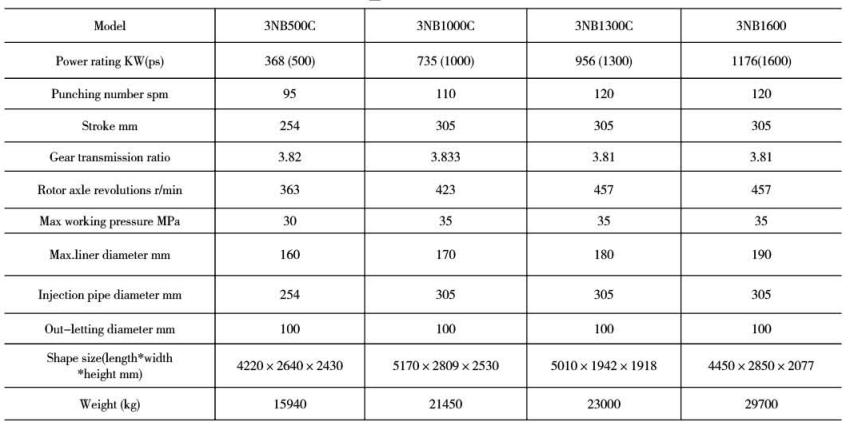

3NB Mud Pump Parameter

High Chrome Bi—Metal Liner

Design and Features

Bi-metal liners are the main expendable parts of the mud pump. They are composed of two metals fixed together. The outer sleeve is forged from high-quality carbon steel, while the inner sleeve is cast from high-carbon, high-chromium steel using centrifugal casting technology. The hardness can reach up to 62 HRC after heat treatment.

To ensure easy installation, tolerances are strictly controlled. The inner sleeve is highly polished and resistant to abrasion and corrosion, making it suitable for harsh working environments and providing a long service life of over 8,000 hours.

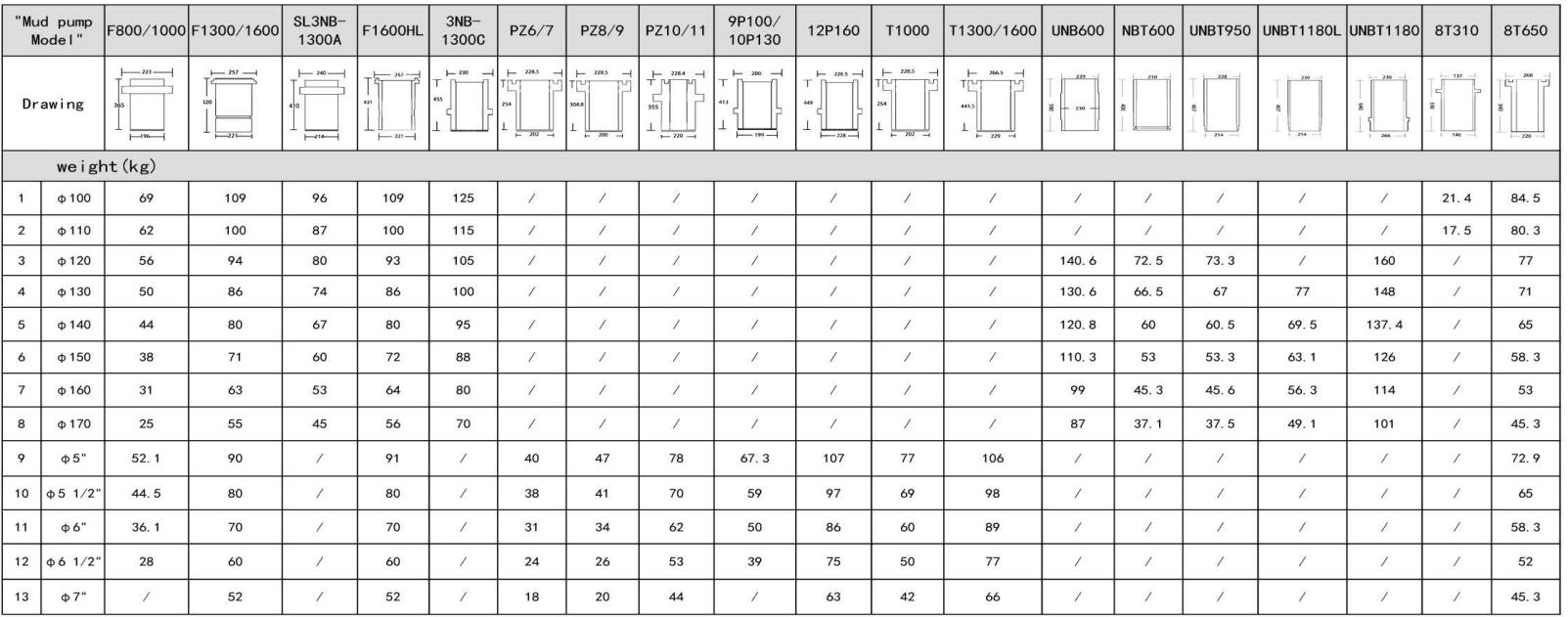

High Chrome Bi—Metal Liner Parameter

Models and Parameters of Liners

MUD PUMP SPARE PARTS

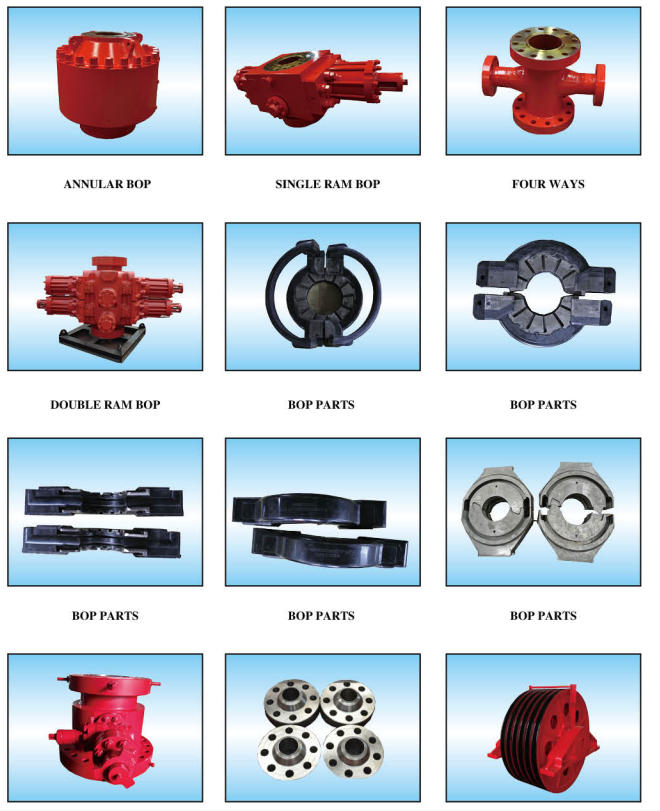

BOP AND SPARE PARTS

THE BIGGEST PUMP PARTS WAREHOUSE IN CHINA

THE BIGGEST PUMP PARTS WAREHOUSE IN CHINA

MUD PUMP REPAIR AND REFABRICATION

WORKSHOPS AND EOUIPMENT