Product Details

Drilling Rig and Parts

Truck-mounted drilling rig

Design and Features

With an optimum structure and high-level integration, the whole rig requires a small working space.

The heavy-duty self-propelled chassis are available in various drive ways 8x6, 10x8, 12x8, 14x8, 14x12, with hydraulic steering system which ensures good drilling accessibility, cruise capability and lateral stability, and also the working reliability of every component.

The matching between the engine and the transmission box ensures high driving efficiency and high working reliability. The drawworks and rotary tables can be driven by motors.

The drilling rig main brake can be band brake or hydraulic disc brake, and the auxiliary brake can be water cooling thrust plate pneumatic brake or water brake.

The rotary table transmission box provides forward-reverse shift, which is suitable for DP make up and break out operations, and is equipped with a reverse torque release device that ensures the DP deformation force releases safely.

The mast, which is front-open and double-sectioned with an inclination angle or with an erective double-section, can be raised up or laid down and telescoped hydraulically.

The drill floor is twin-body telescopic type or parallelogram structure, which is convenient for hoisting and transportation. The dimension and height of the drill floor can be designed based on customers' requirements.

The configurations of the solid control system, well control system, high-pressure manifold system, generator house, engine pump house, doghouse and other auxiliary equipment can meet the different requirements of the end-users.

Truck-mounted drilling rig Technical Parameter

|

Model |

ZJ10/900CZ |

ZJ15/1350CZ |

ZJ20/1580CZ |

ZJ30/1700CZ |

ZJ40/2250CZ |

|

Drilling Depth (ft) (41/2″ DP) |

1000 |

1500 |

2000 |

3000 |

4000 |

|

Workover Depth (ft) (31/2″ DP) |

2500 |

4500 |

5500 |

6500 |

7000 |

|

Max Hook **** (KN) |

900 |

1350 |

1580 |

1800 |

2250 |

|

Hook speed (m/s) |

0.2 ~ 1.4 |

||||

|

Mast height (m) |

29/31 |

33 |

35 |

36/38 |

38 |

|

Mast type |

Mast |

Mast |

Mast |

Mast or Erection |

Mast or Erection |

|

Engine power (Hp) |

350 |

540 |

630 |

2×540 |

2×630 |

|

Hydraulic transmission box |

4700 |

S5610HR/TH35 |

S6610HR |

2×S5610HR |

2×S6610HR |

|

Drive ways |

Hydraulic + mechanical |

||||

|

Traveling system |

4×3 |

5×4 |

5×4 |

6×5 |

6×5 |

|

******** **** diameter (in/mm) |

1” / φ26 |

1” / φ26 |

1-1/8 ” / φ29 |

1-1/4” / φ32 |

1-1/4” / φ32 |

|

Hook block |

YG90 |

YG110 |

YG160 |

YG180 |

YG225 |

|

Swivel |

SL110 |

SL135 |

SL160 |

SL225 |

SL225 |

|

Rotary table |

ZP175 |

ZP175 |

ZP175 |

ZP205/ZP275 |

ZP275 |

|

Chassis |

XD40/8×6 |

XD50/10×8 |

XD60/12×8 |

XD70/14×8 |

XD70/14×8 |

|

Approaching /Departure angle |

22° /18° |

30° /20° |

26° /18° |

26° /18° |

26° /18° |

|

|

|

||||

|

Max. gradient ability |

30% |

26% |

26% |

26% |

26% |

|

Min. turning diameter (m) |

28 |

30 |

38 |

41 |

41 |

|

Overall dimension(m) |

16.7×2.8×4.2 |

18.8×2.9×4.3 |

20.5×2.9×4.4 |

22.3×3.0×4.5 |

22.3×3×4.5 |

|

Main unit mass(kg) |

50000 |

58000 |

65000 |

80000 |

85000 |

Workover Rig

Design and Features

The whole machine is reasonable in structure, high degree of mechanization, small floor area. Powered by the hydraulic and mechanical transmission, high efficiency; optional two - use special chassis chassis or self-propelled chassis and other forms, to meet the various needs of customers.

The derrick with single and double opening package, hydraulic lift, hydraulic or mechanical stretching.

The main winch brake can adopt band brake or a hydraulic disc brake, auxiliary brake can adopt pneumatic water push type brake, brake and other forms of water.

The floor is two body telescopic or parallelogram stru cture, convenien t transportation and hoisting, the table size and height can be designed according to user requirements.

Workover Rig Technical Parameter

| Mode | XJ350 | XJ450 | XJ550 | XJ650 | XJ750 | XJ1000 |

| 73mm External-thickened tube | 4000m | 5500m | 7000m | 8500m | ||

| 73mm DP | 3200m | 4500m | 5800m | 7000m | 8000m | 9000m |

| 88.9mm DP | 2500m | 3500m | 4500m | 5500m | 6500m | 7500m |

| 114mm DP | 3600m | 4200m | 5000m | 6000m | ||

| Max.hook load, KN | 900 | 1100 | 1350 | 1600 | 1800 | 2250 |

| Rated hook load, KN | 600 | 800 | 1000 | 1200 | 1500 | 1800 |

| Drawwork type | Single drum/Double drum | |||||

| Drawwork power, KW(hp) | 350 | 450 | 550 | 650 | 750 | 1000 |

| Drawwork hoisting gears | 5+1R | |||||

| Brake mode | Band/disc brake + rotor hydromatic brake / disc water-cooling brake | |||||

| Line strung of traveling system | 3×4 | 4×5 | 5×6 | |||

| Dia. of drilling wire rope, mm(in) | Ф26(1) | Ф29(1-1/8) | Ф29(1-1/8) | Ф32(1-1/4) | ||

| Mast type | Mast-type double-section hydraulic hoisting | |||||

| Mast height (m) | 29,31 | 31,33,34,35 | 35,36 | 36,38 | 38,39,41 | |

| Drive mode of chassis | 8×8/10×8 | 10×8 | 12×8 | 14×8 | 14×8 | |

Crown block

Design and Features

Way of perforating belt is clockwise.

It boasts crown block perch that is made of highly intense material and steel plate. It has overhead driving installing lug. It is equipped with metal support plate、rectangle pipe guardrail and foot retainer. Also it has stair opening.

Working pulley group is placed leaning, which offsets the twist of idler car, and makes the side bar of idler car facing front face of derrick. It is convenient for plucking hanging card.

It has a polarization fast line pulley.

Pulley belt slot is middle quenched to improve the surface hardness in order to prolong the using life of pulley.

All the pulleys are equipped with double awl rolling bearing, each with independent lube pipe.

It is equipped with belt retainer stick to prevent cordage from hopping or sloughing.

It is equipped with collision-proof baffling wood, and protecting network.

It is equipped with transporter ,which is used for maintaining pulley group.

It is equipped with bailing pulley and auxiliary pulley.

Pulley and bearing can change with assorted idler car.

The crown block accords with API Spec 4F regulations, and association’s emblem is allowed.

Crown block Technical Parameter

|

Model |

TC135 |

TC170 |

TC225 |

TC315 |

TC450 |

TC585 |

|

Biggest hook load(kN) |

1350 |

1700 |

2250 |

3150 |

4500 |

5850 |

|

Pulley outside diameter |

915 (36 ") |

1005 (40") |

1120 (44") |

1120 (44") |

1524 (60") |

1524 (60") |

|

Pulley number |

5 |

6 |

6 |

7 |

7 |

8 |

|

Hoisting cable diameter (mm in) |

29(11/8") |

29(11/8") |

32(11/4") |

35(13/8") |

38(11/2") |

42(15/8") |

|

Shape size(length*width*height mm) |

2500×2050 ×1920 |

2687×2150 ×2046 |

3200×3347 ×3640 |

3295×2776 ×2514 |

3068×2906 ×3576 |

3070×3000 ×3600 |

|

Weight(kg) |

2400 |

2920 |

5310 |

7400 |

9500 |

10000 |

Traveling block

Design and Features

The lateral plate is a thick section armor plate with heavy enough weight. The steel wire is always in tension while lifting and demoting, which serves to wire rope for the roller and control the demoting speed for the empty hook and to prolong the life expectancy of steel wire.

Pulley belt slot is middle quenched to improve the surface hardness in order to prolong the using life of pulley.

All the pulleys are equipped with double awl rolling bearing, each with independent lube pipe.

It boasts modulated steel bearing, with single pulley bearing grease lubricant hole.

It boasts heavy-duty steel wire protecting cap.

It boasts high strength steel wire swinging ring.

Pulley and bearing can change with assorted crown block.

The traveling block accords with API Spec 8A regulations, and API association’s emblem is permitted.

Traveling block Technical Parameter

|

Model |

YC90 |

YC135 |

YC170 |

YC225 |

YC315 |

YC450 |

YC585 |

|

Max hook load(kN) |

900 |

1350 |

1700 |

2250 |

3150 |

4500 |

5850 |

|

Pulley outside diameter |

762 (30") |

915(36") |

915(36") |

1120(44") |

1270(50") |

1524(60") |

1524(60") |

|

Pulley number |

4 |

4 |

5 |

5 |

6 |

6 |

7 |

|

Hoisting cable diameter (mm in) |

26 (1") |

26 (1") |

29(11/8") |

32(11/4") |

35(13/8") |

38(11/2") |

42(15/8") |

|

***** size(length*width*height mm) |

1500×806 ×533 |

1800×960 ×610 |

2100×960 ×630 |

2294×1190 ×630 |

2680×1350 ×974 |

3075×1600 ×800 |

3100×1600 ×965 |

|

Weight(kg) |

1810 |

2200 |

3010 |

3805 |

6842 |

8135 |

9600 |

Hook

Design and Features

Hydraulic buffering equipment is installed to protect drill pipe tie-in while breaking out.

Reliable security facility is installed in the mouth of hook.

All the main components stressed of the rotary hook are through nondestructive flaw detection.

The rotary hook accords with API Spec 8A regulations, and API association's emblem is permitted.

Hook Technical Parameter

|

Model |

DG90 |

DG135 |

DG170 |

DG225 |

DG315 |

DG450 |

DG585 |

|

Max ******** (kN) |

900 |

1350 |

1700 |

2250 |

3150 |

4500 |

5850 |

|

Opening size of chief hook mouth(mm in) |

155(61/16) |

165(61/2) |

180 (7) |

190(71/2) |

220(85/8) |

220(85/8) |

238(9 3/8) |

|

Diameter of chief hook mouth(mm in) |

116(41/2) |

140(5 1/2) |

140(51/2) |

160(61/4) |

180 (7) |

180 (7) |

180 (7) |

|

Diameter of auxiliary hook mouth(mm in) |

80(31/8) |

90(31/2) |

90(31/2) |

100(4) |

120(43/4) |

120(43/4) |

120(43/4) |

|

Spring working process (mm in) |

180(7) |

180(7) |

180 (7) |

180 (7) |

180 (7) |

180 (7) |

180 (7) |

|

Shape size(length*width*height mm) |

2000×680×600 |

2200×720×616 |

2450×750×630 |

2545×780×750 |

2953×890×830 |

2950×890×880 |

3156×930×930 |

|

Weight(kg) |

1800 |

1910 |

2020 |

2180 |

3410 |

3496 |

3900 |

Swivel

Design and Features

It is equipped with standard hanging ring and double pin thread alloyed pipe nipple.

The washing pipe and packing facility are boxlike structure, which can be changed rapidly on the rig floor. Never tear apart water hose and gooseneck tube.

The top through-hole of the gooseneck tube provides detecting hoisting cable with passage.

It boasts standard gooseneck tie-in. The screw thread accords with API standard 5B.

The swivel accords with the API Spec 8A regulation, and API association’s emblem is permitted.

It can be equipped with double-purpose swivel at the requirements of customers.

Swivel Technical Parameter

|

Model |

SL90 |

SL135 |

SL225 |

SL450 |

SL585 |

|

|

Biggest **** load(kN) |

900 |

1350 |

2250 |

4500 |

5850 |

|

|

Highest revolution |

300 |

300 |

300 |

300 |

300 |

|

|

Highest working pressure(MPa (psi) |

25(3570) |

35(5000) |

35(5000) |

35(5000) |

35(5000) |

|

|

Clearance between hanging ring and gooseneck tube(mm in) |

435(171/8) |

495(191/2) |

540(211/4) |

549(215/8) |

584(23) |

|

|

Central duct (mm in) |

64(21/2) |

64(21/2) |

75 (3) |

75 (3) |

75 (3) |

|

|

Weight(kg) |

1810 |

2200 |

3010 |

3805 |

6842 |

|

|

Upper screw of central tube tie-in |

Connecting central tube APA(regu lar) in |

41/2 REG LH |

41/2 REG LH |

65/8 REG LH |

75/8 *** LH |

75/8 REG LH |

|

Under-part screw of central tube tie-in |

Connecting Kelly bar API( regular) in |

65/8REGLH |

65/8REGLH |

65/8REGLH |

65/8REGLH |

65/8REGLH |

|

Gooseneck tube tie-in screw |

3”-8teeth/inch |

3”-8teeth/inc |

4”-8teeth/inch |

4”-8teeth/inch |

4”-8teeth/inch |

|

|

Shape size(length*width*height mm) |

2505×758×840 |

2505×758×840 |

2880×1026×1065 |

3015×1096×1065 |

3115×1224×990 |

|

|

Weight(kg) |

940 |

1345 |

2402 |

3310 |

3530 |

|

Rotary Table

Design and Features

Pin transmission type can be placed in API standard square drill pipe or six-square roller bushing,. Either long or short slips cab be used.

Split chief bushing is steel casting., which can provide two models: square transmission or pin transmission.

Rotary tables accords with API Spec 7K regulations, and API association's emblem is permitted.

It is equipped with API standard thimble bushing and hanger of exclusive use.

Both big and small pulleys are made of alloy steel materials.

The rotary table is fully lubricated and reliably airproofed.

Rotary Table Technical Parameter

|

Model |

ZP175 |

ZP205 |

ZP275 |

ZP375 |

ZP495 |

|

Pylome diameter(mm in) |

444.5(171/2) |

520.7(201/2) |

698.5(271/2) |

952.5(371/2) |

1257.3(491/2) |

|

Width between centers(** in) |

1118(44) |

1353 (531/4 ) |

1353(531/4 ) |

1353(531/4 ) |

1651(65) |

|

Max. dead load(kN) |

1350 |

3150 |

4500 |

5850 |

7200 |

|

Max. working torque(Nm) |

14000 |

23000 |

28000 |

33000 |

37000 |

|

Max. revolution(r/min) |

300 |

350 |

250 |

300 |

300 |

|

Gear ************ ratio |

3.58 |

3.22 |

3.67 |

3.56 |

3.93 |

|

Shape size(length*width*height mm) |

1935×1280×585 |

2292×1475×668 |

2392×1670×685 |

2468×1810×718 |

2940×2184×813 |

|

Weight (kg) |

3888 |

5530 |

6163 |

8026 |

11626 |

Winch

Design and Features

It boasts highly precise、highly strong transmission chain, which enforces lubrication.

All the bearings adopt roller bearing, axis material being alloy steel

Rollers' notching. The high and low speed extreme both are ventilated type pneumatic tyre clutch. Brake disk adopts cycling water enforcing cooling and is middle quenched , which makes it hard in wearing and longer in using life.

Chain pulley's tooth profile is middle quenched. All the stage changeover clutches are involute splining clutch.

The chief brake adopts belt type or disk type, while the auxiliary brake is equipped with electromagnetic swirl brake,( water cooled or wind -cooled).

Winch Technical Parameter

|

Model |

JC40 |

JC50 |

JC70 |

|

|

Nominal drilling depth (m) |

Ф114mmdrillpipe |

2500-4000 |

3500-5000 |

4500-7000 |

|

Ф127mmdrillpipe |

2000-3200 |

2800-4500 |

4000-6000 |

|

|

Power rating(kW HP) |

735 (1000) |

1100 (1500) |

1470 (2000) |

|

|

Max.fast **** pull(kN) |

275 |

340 |

485 |

|

|

Hoisting cable diameter(mm in) |

32 (11/4 ) |

35 (13/8 ) |

38 (11/2) |

|

|

Roller(diameter*length)mm in |

640 ×1235 (25 1/4 ×48 1/2 ) |

685×1245 (27 ×49 ) |

770×1436 (30 ×56 1/2 ) |

|

|

Brake pulley (diameter*length)mm in |

1168×265 (46 ×10 1/2 ) |

1270×267 (50 ×10 1/2) |

1370×267 (54 ×10 1/2 ) |

|

|

Brake disk(diameter*length)mm in |

1500×76 (59×3) |

1600×76 (63×3 ) |

1600×76 (63×3 ) |

|

|

Sand **** capacity(Ф14.5 Hoisting cable) m(ft) |

3500(11480 ) |

4500(14760 ) |

6000(19685 ) |

|

|

Auxiliary brake |

DS40 |

DS50 |

DS70 |

|

|

Shape size (length* width*height mm) |

6450×2560×2482 |

7000×2955×2780 |

7930×3194×2930 |

|

|

Weight (kg) |

28240 |

45210 |

43000 |

|

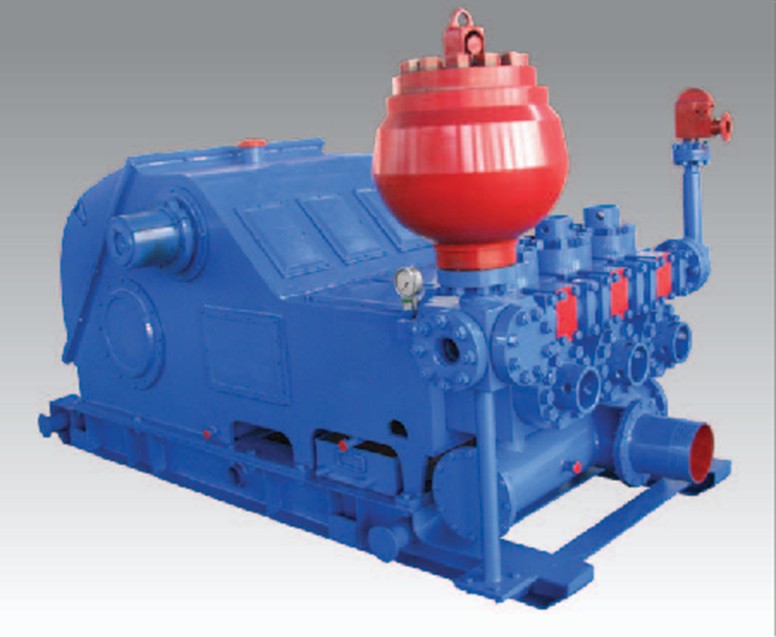

F Serial Mud Pump

Design and Features

Fserial mud pump has longer stroke, which makes it able to be used under lowerpunching number to prolong the use life of sensitive parts in fluid end.

The combination lubricating method of forced lubrication and spray lubrication ensuresthe more effeetive lubrication.

The durable and compact F serial mud pump with advanced structure improvespump's stable operation, lt can meet special demands of customers in middle & deepdrilling works.

It's small and durable, The injection valve and bleed valve can change mutually, soean the three cylinders of each pump and main parts of Пuid end.

The durable fuid end of F serial mud pump improves the performanee of triplexmud pump greatly, Besides, its independent design is convenient to be examined andmaintained.

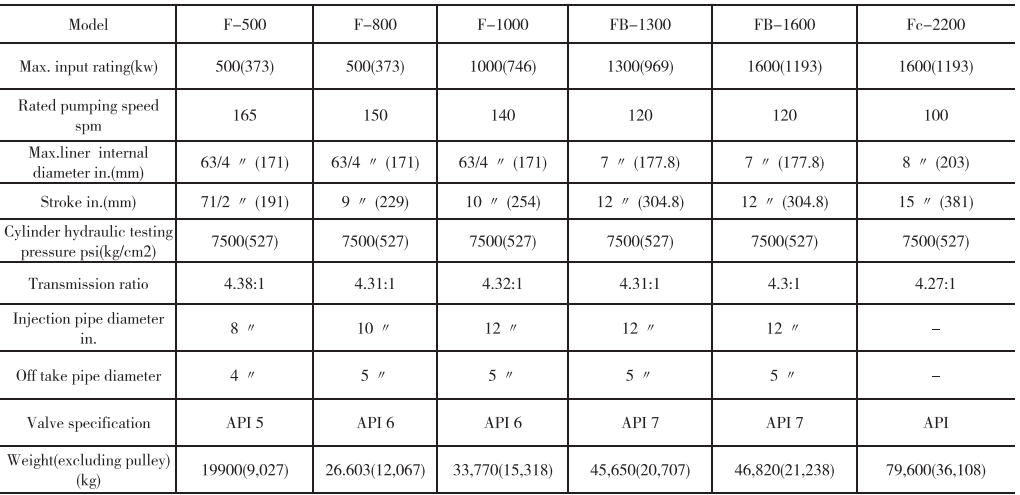

F Serial Mud Pump Technical Parameter

3NB Mud Pump

Design and Features

Power point: The shell is of plate welding structure, which eliminates internal stress after welding. The power point transmission gear is involute gear type, which is of stable operation、high proficiency and long use life. The crank is a hollow complete cast, and way of lubricating is spray lubrication.

The bottom of the valve hole has steps to prevent clack seat from falling. The piston and liner is cooled and lubricated by an independent spray pump equipment, which boasts long use life.

The piston and in-between beam are connected by lathe dog, which can achieve rapid installing and moving.

Liquid point: The injection and out letting flange accords with ASA&API regulations.

The sensitive parts has strong commonality.

3NB Mud Pump Technical Parameter

|

Model |

3NB500C |

3NB1000C |

3NB1300C |

3NB1600 |

|

Power rating KW(ps) |

368 (500) |

735 (1000) |

956 (1300) |

1176(1600) |

|

Punching number spm |

95 |

110 |

120 |

120 |

|

Stroke mm |

254 |

305 |

305 |

305 |

|

Gear ************ ratio |

3.82 |

3.833 |

3.81 |

3.81 |

|

Rotor axle revolutions r/min |

363 |

423 |

457 |

457 |

|

Max working pressure MPa |

30 |

35 |

35 |

35 |

|

Max.liner diameter mm |

160 |

170 |

180 |

190 |

|

Injection pipe diameter mm |

254 |

305 |

305 |

305 |

|

Out-letting diameter mm |

100 |

100 |

100 |

100 |

|

Shape size(length*width *height mm) |

4220×2640×2430 |

5170×2809×2530 |

5010×1942×1918 |

4450×2850×2077 |

|

Weight (kg) |

15940 |

21450 |

23000 |

29700 |

Single Arm Elevator Links

Design and Features

The design and fabrication conform to API Spec 8A, API Spec 8C, SY/T5035 and other relevant technical specifications, with a national fabrication license.

It's made of high quality alloy steel created by a forging process.

Finite-element analysis is adopted for strength checking and electrical measurement for stress testing. There are two kinds of elevator links, including the single arm type and the double arm type.

More effective sand blasting process is adopted to intensify the surface of the links

Single Arm Elevator Links Technical Parameter

|

Model |

Rated load(Ibf) |

Working length(ft) |

Overall dimension(ft) |

Weight (Ib) |

|

DH150 |

303492 |

5.91 |

6.50×0.89×0.33 |

132.28 |

|

DH250 |

505820 |

8.86 |

9.51×1.18×0.36 |

330.69 |

|

DH350 |

708148 |

10.83 |

11.48×1.27×0.43 |

498.24 |

|

DH500 |

1000360 |

12.46 |

12.68×1.61×0.52 |

868.61 |

Drilling House and Fittings

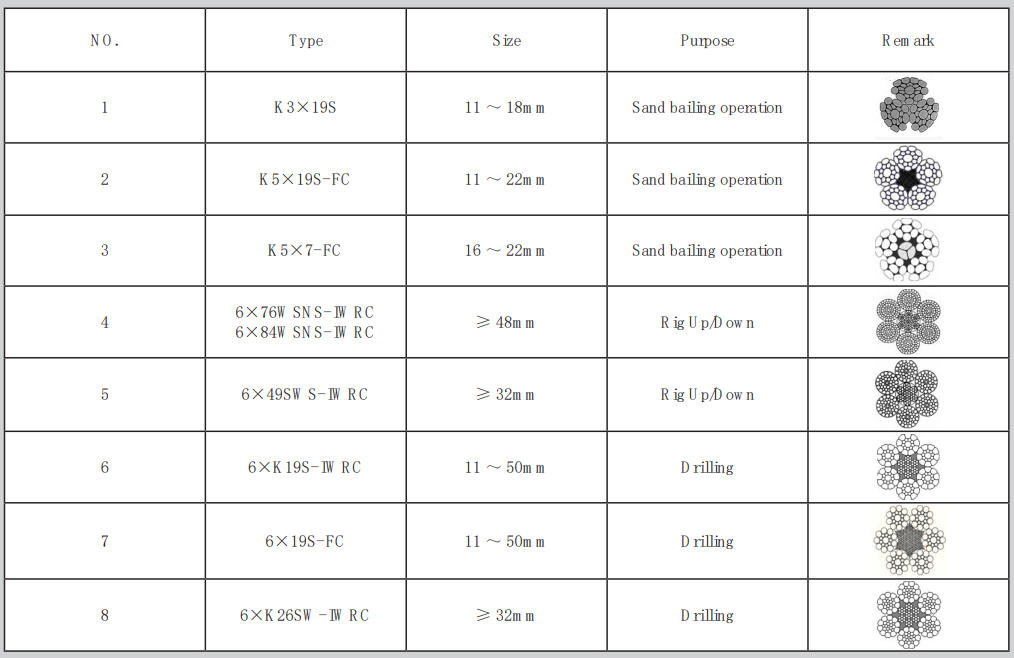

Drilling Line

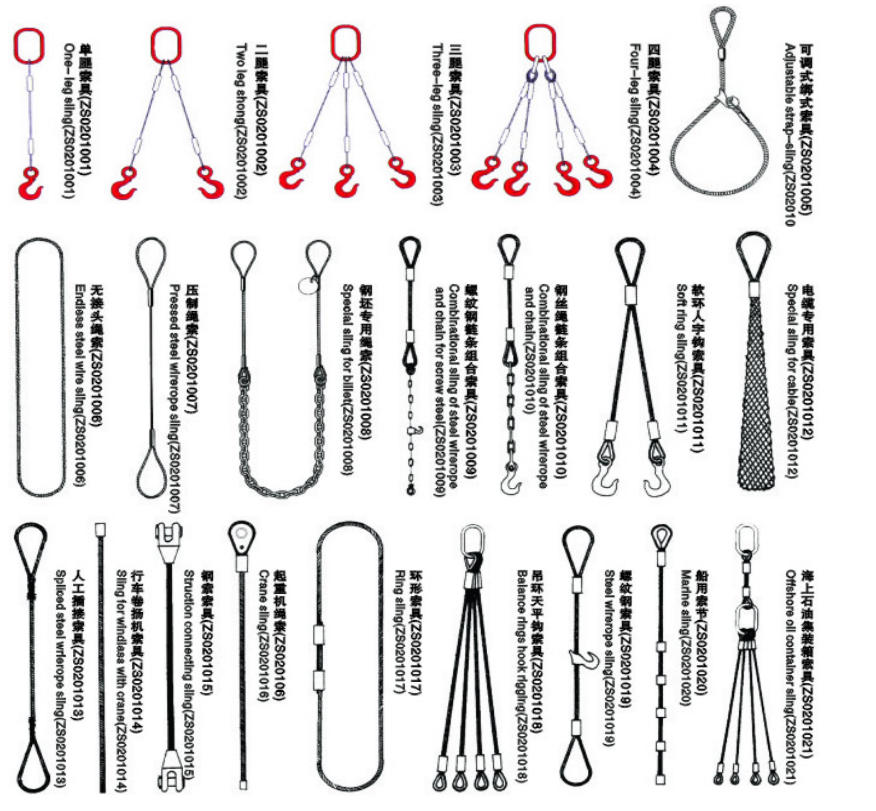

Wire Rope Sling

Wheels and tires

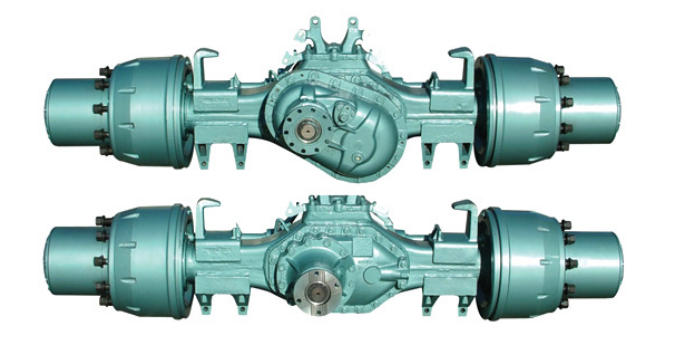

Vehicle axle

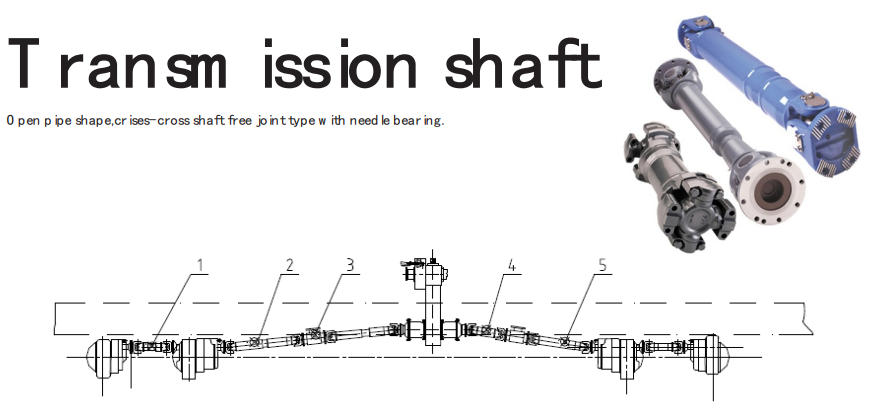

Transmission shaft

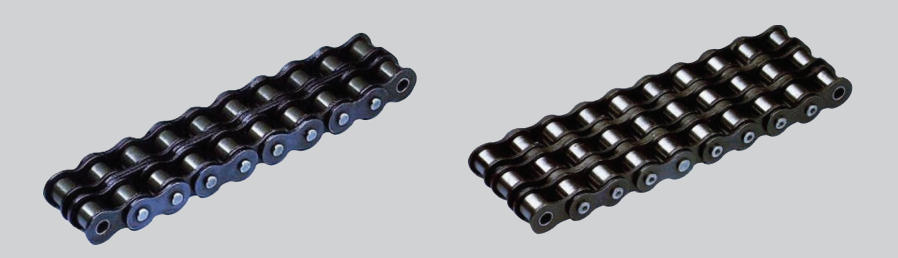

The chain for the drilling rigs

Applicable to the winch, climbing chain box. Recommended for deep drilling rig and export special chain

|

GB chain no. |

Pitch |

Roller diameter |

Inner width ** inner ***** link |

Bearing pin diameter |

***** height |

Plate height |

Array pitch |

Bearing pin length |

Additional width of lock device |

Tensile load |

Weight/m |

|

P |

d1 (max) |

b1(min) |

d2 (max) |

s(max) |

h2(max) |

Pt |

L(max) |

c |

(min) |

|

|

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

kN |

kg/m |

|

|

16AH-1 |

25.40 |

15.87 |

15.75 |

7.94 |

3.96 |

24.13 |

|

35.9 |

3.6 |

82.1 |

3.20 |

|

16AH-2 |

25.40 |

15.87 |

15.75 |

7.94 |

3.96 |

24.13 |

32.59 |

68.4 |

3.6 |

164.2 |

6.34 |

|

20AH-1 |

31.75 |

19.05 |

18.90 |

9.54 |

4.75 |

30.18 |

|

42.9 |

4.0 |

119.2 |

4.71 |

|

20AH-2 |

31.75 |

19.05 |

18.90 |

9.54 |

4.75 |

30.18 |

39.09 |

82.0 |

4.0 |

238.4 |

9.33 |

|

24AH-1 |

38.10 |

22.22 |

25.23 |

11.11 |

5.56 |

36.20 |

|

53.3 |

4.2 |

163.3 |

6.72 |

|

24AH-2 |

38.10 |

22.22 |

25.23 |

11.11 |

5.56 |

36.20 |

48.87 |

102.2 |

4.2 |

326.6 |

13.35 |

|

40AH-1 |

63.50 |

39.67 |

37.85 |

22 |

9.52 |

60.33 |

|

84.6 |

6.6 |

440 |

20.0 |

|

40AH-2 |

63.50 |

39.67 |

37.85 |

22 |

9.52 |

60.33 |

78.31 |

162.9 |

6.6 |

880 |

39.2 |

|

40AH-3 |

63.50 |

39.67 |

37.85 |

22 |

9.52 |

60.33 |

78.31 |

241.2 |

6.6 |

1320 |

58.5 |

Eaton WCB Auxiliary brake

Design and Features

Eaton WCB series of water-cooled brake hydraulic brake WCB Eaton brake applied to absorb large power applications. For the design of copper alloy friction disc brake heat generated by the rapid transfer to the circulating water cooling system, is installed in the main winch drum shaft, with brake disc brake use, is the indispensable part of drilling winch. Often as rig workover rig auxiliary brake use

They are widely used in Oilfield auxiliary equipment, papermaking industry, printing industry, ship, port and other winch equipment under the condition of heavy braking and tension control.

Specifications: WCB124, WCB224, WCB324, WCB424, WCB136

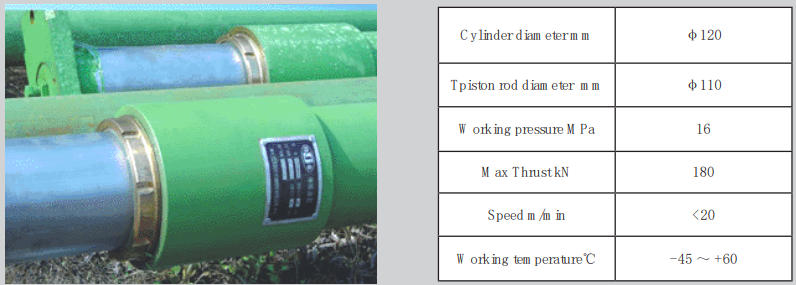

Mast up hydraulic cylinder

Mast Telescopic hydraulic cylinder

Hydraulic leg cylinder